The Effect Of Hydrogen In Steel

Preheat temperatures on steel pipe and many steel structures are arrived at by taking into consideration the carbon equivalent (Ceq%) of the material, the material thickness and the arc energy or heat input (kJ/mm). Reference may be made to standard specifications, e.g. BS EN 1011 – Process of arc welding of carbon and carbon manganese steels, which define preheat temperatures based on Ceq%*, thicknesses and arc energy.

- Carbon equivalent %

The welding inspector would usually find the preheat temperatures to be used from the relevant welding procedure.

The Ceq% of a steel primarily relates to its hardenability. If a steel has a relatively high Ceq% it will be more susceptible to hardening in the heat affected zones of any welds made, in comparison with welds made on steels of low Ceq%. Hardenability affects weldability, therefore materials of high Ceq% are considered more difficult to weld.

The Ceq% of a material depends on its alloying elements; the typical elements in a high-grade carbon manganese steel are as follows:

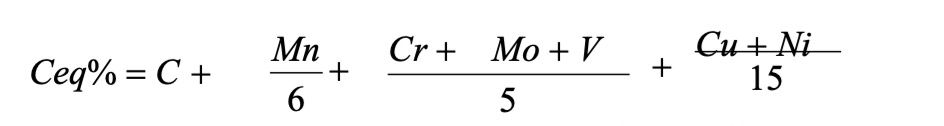

The Ceq% of a steel is usually calculated from the I.I.W. carbon equivalent formula:

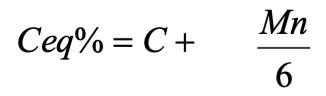

Only carbon and manganese have any significant effect on the final Ceq% figure on carbon/carbon manganese steels, therefore the formula may sometimes be shortened to:

The manganese content is divided by 6 because it has one sixth of the

effect of carbon in relation to hardenability.

A carbon equivalent value less than approximately 0.4% would be considered low for a low alloy steel (this includes C-Mn steel).

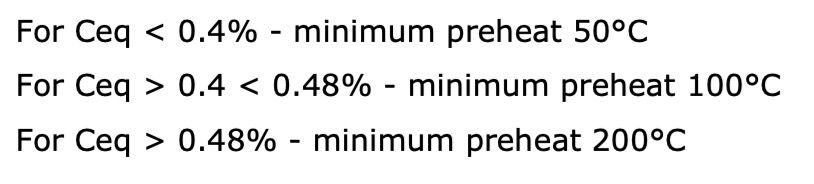

A typical specification example of preheat temperatures for C-Mn steel 8-20mm thick is as follows:

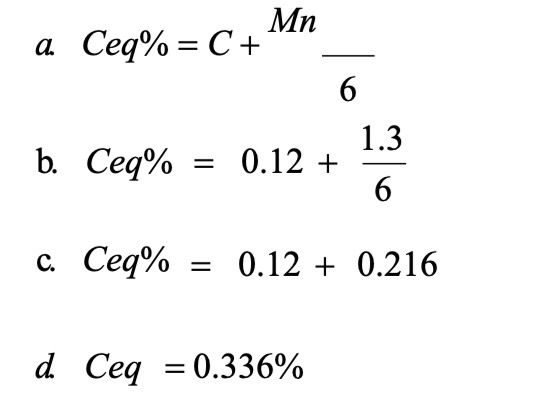

EXAMPLE:

What is the Ceq% of a steel which contains 0.12% carbon and 1.3% manganese?

Thicker materials normally require higher preheat temperatures, however, for a given Ceq% and arc energy, the preheat temperature is likely to be the same for wall thicknesses up to approximately 20 mm.